Application:

- Wafer Size : 150mm, 200mm and 300mm

Available Process:

- Dry Ox, Wet Ox, Annealing

Experience:

- 850℃ to 1250℃ Atmospheric

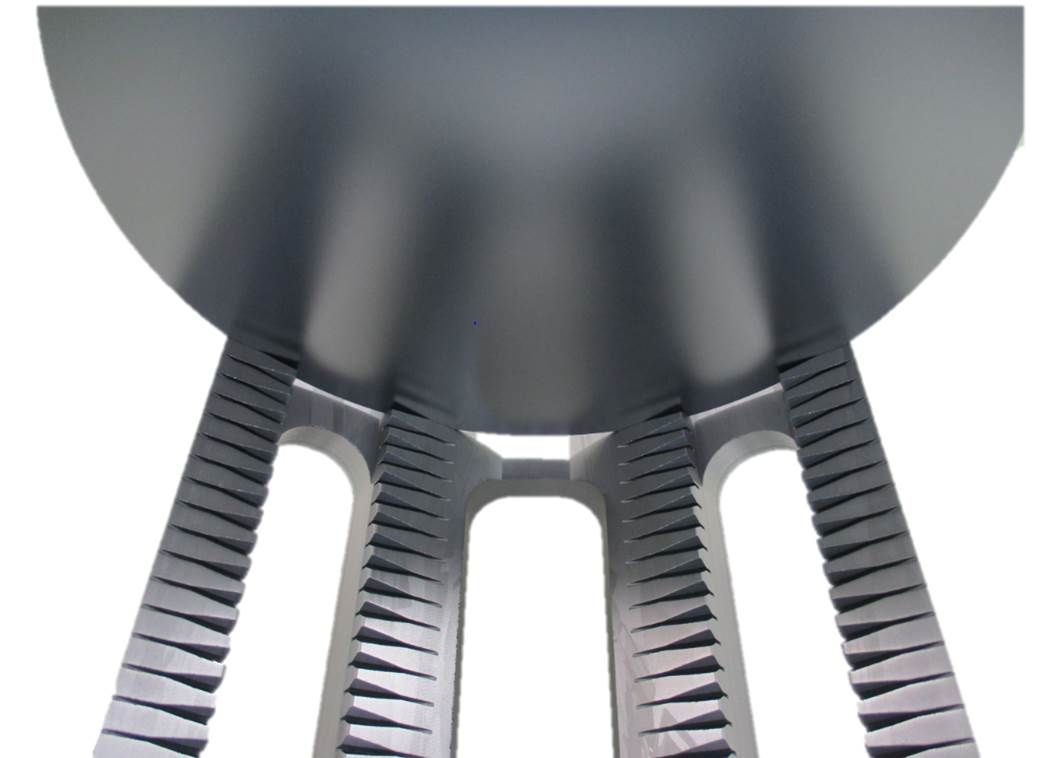

Advantages of Si-Boat

Reduced defect density and particle counts leading to yield improvement

- Using silicon vs quartz or SiC

- Using mono crystal vs poly crystal silicon (no CVD growing defects )

- Sophisticated rod designLess overlap rod to wafer

Lower metal contamination

- No metal impurities in silicon as in quartz or SiC

No slip lines or crystal damages

- No friction caused by identical thermal expansion of boat and wafer

- No warp of the boat as it uses quartz material for high-temperature process

Savings during processing

- Increased tool uptime compared to quartz and SiC boats

- Less cost of cleaning and maintenance

- Repairable and customizable