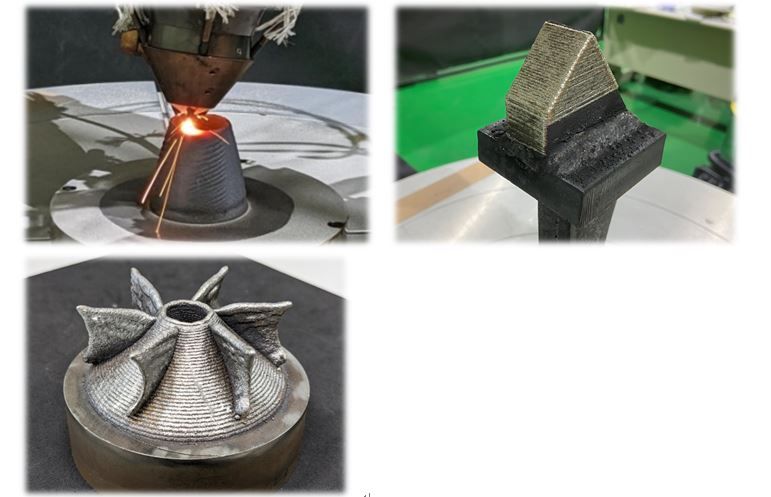

Laser cladding uses high power laser beam to heat the surface of the workpiece, while injecting metal powders to the melting pool. The molten powders are solidified and form a solid coating on the surface. Combining a CNC machine or a robot, the system can produce thick claddings on complex geometry surfaces or for additive manufacturing. Due to the strong metallurgical bonding between the molten powders and the substrate, the joint junction has great mechanical properties. In addition, the rapid heating and cooling of the process results in very low dilution and HAZ. Laser cladding is usually used to apply wear-resistant coatings or repairing the worn parts in heavy-duty machines. It can also be applied to the manufacturing and repairing parts of difficult-to-cut materials or special alloys. We have developed processes for many materials, such as tool steels, stainless steels, nickel alloys, cobalt-alloys, and carbides.