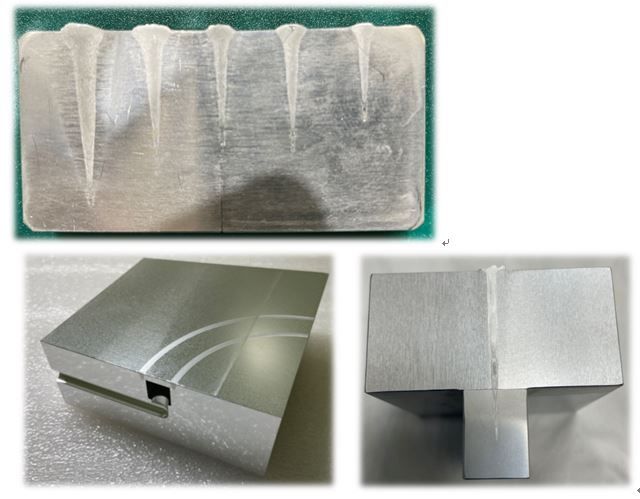

Electron beam welding (EBW) uses high-speed electrons to bombard the workpiece causing rapid melting and cooling of the material to weld the workpiece. The process is carried out in a vacuum, thus greatly reduces the oxidation and contaminations of the weld bead. It is one of the cleanest and strongest welding processes. In addition, EBW has high penetration and low HAZ. The depth of the weld bead can reach tens of millimeters deep and the aspect ratio can be greater than 50. It is often used for butt joints, T-joints, and lap joints welding, especially for special occasions where the joints are constrained or limited by the geometry.

We have the most advanced equipment and technology to precisely control the electron beam and its oscillation, and perform complex and reliable welding. The large vacuum chamber can accommodate workpieces over 1 meter in length. The process can be applied on most metals and between some dissimilar materials.