Technical Capability - Automation System Design and Integration

In the highly competitive and precision-demanding manufacturing industry, we leverage semiconductor-grade craftsmanship, service experience, extensive know-how, and unique innovative technologies

to provide customized automation system design and integration services. We help clients improve production efficiency, stabilize product quality, and reduce labor and

supply chain management costs. Our professional engineering team covers the entire process from requirement analysis, system planning, mechanical design to full-line assembly and testing—

all centered on precision, efficiency, and flexibility—to deliver automation solutions tailored to clients’ process needs.

Mechanical Design

Using modeling systems, we conduct customized mechanical design based on client requirements, supplemented with basic simulation analysis through engineering software.

HMI Systems

We work with various brands of Human-Machine Interfaces (HMI), providing customized design and installation based on different user requirements.

Electrical Control Design

For electrical control in automation systems or equipment, we use computer-aided design software to plan circuits and hardware layouts.

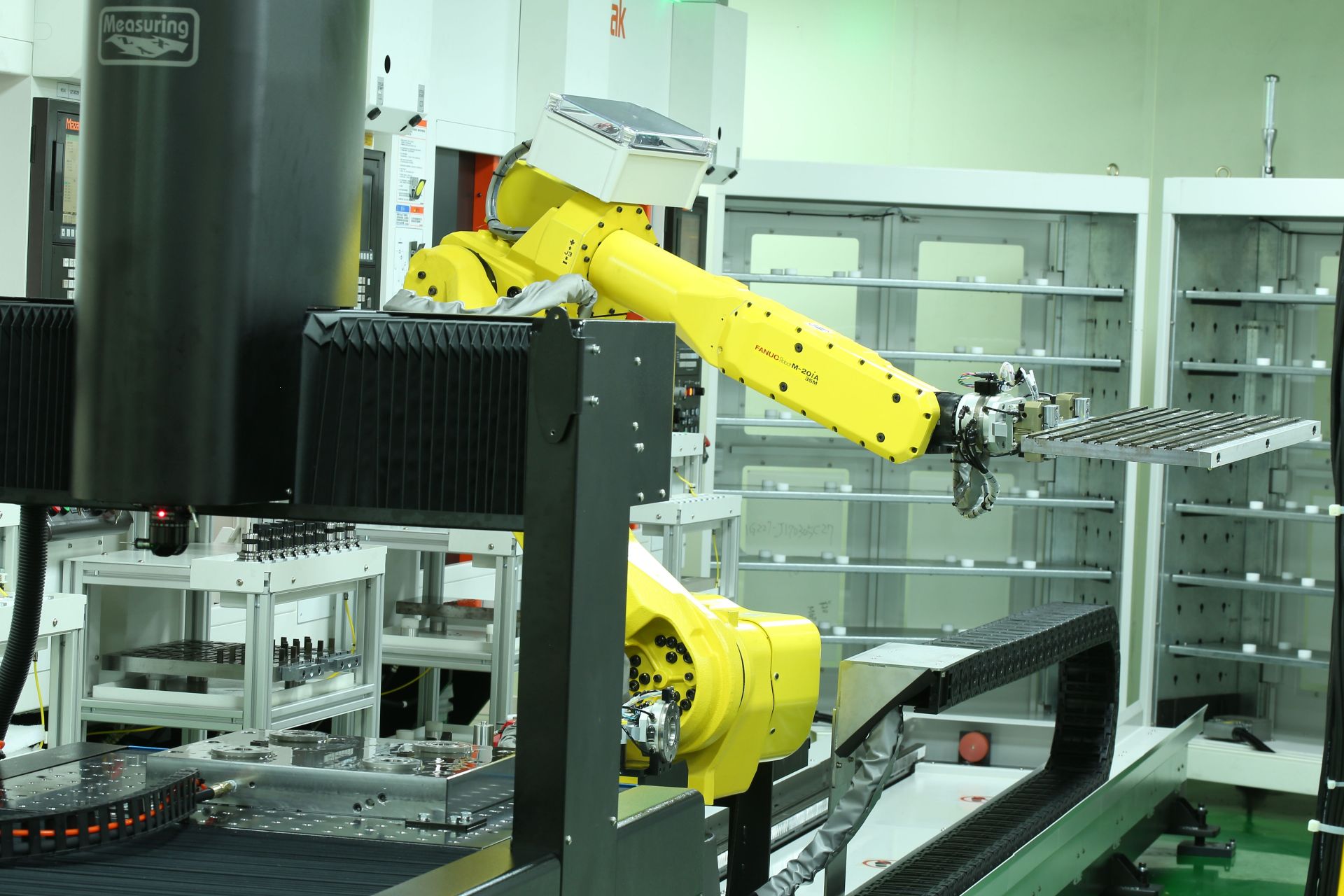

Robotic Arms

Primarily using collaborative robotic arms, we assist in internal automation production and can also provide technical support and services based on client needs.

Service Team

A dedicated service team is responsible for automation system assembly, after-sales service, and maintenance, ensuring prompt support within designated timelines.

Project Showcase

|

|

|

One-to-Many Automated Production Line Planning |

Automated Laser Cleaning Machine |

|

|

|

Surface Purification Automated Production Line Development |

Automated Electronic Dashboard Software Integration |